Semboo has some unique skills to eliminate the deformation of aircraft parts

发布时间:2019/12/11

As we all know, an airplane is a very precise and complex machine. Taking Boeing 747-400 as an example, an airplane costs 150 million US dollars. The whole machine is composed of more than 6 million various parts. Each part is very important and very expensive.The shape of most parts is special and the surface is complex, which belongs to light thin-walled parts, and it is easy to produce deformation.The main causes of the deformation are the deformation caused by the machining process and the deformation caused by the internal residual stress of the workpiece after the machining.

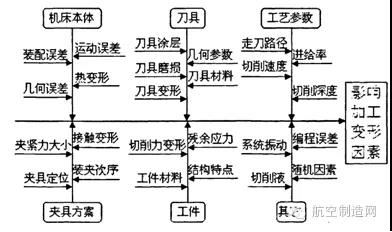

In addition to the above two main reasons, there are many other reasons for the deformation of aviation parts. Raw materials are related to the material of blank, the geometry of parts, production process, tool selection and workshop environment. More specific factors are shown in the figure below:

1. Initial residual stress of raw material blank

Residual stress, also known as internal stress, refers to the stress remaining in the workpiece after all external loads are removed.The residual stress is caused by the inhomogeneous volume change of the internal structure of the metal.In the process of workpiece production, residual stress has existed in the blank stage, which keeps the balance of the whole structure of the blank.In the process of processing and processing, uneven deformation or phase transformation occurs in the local area of the blank, which will inevitably lead to the generation of residual stress in the workpiece.

With the gradual removal of the blank during the forming process, the original balance condition is destroyed, and the residual stress of the blank itself is released gradually to cause deformation, so as to achieve a new balance state, which is the basic principle of the workpiece deformation caused by the residual stress release.

2. Effect of tool on workpiece

Cutting heat: in the process of cutting, the work done by the friction between the tool and the workpiece is converted into cutting heat, resulting in the uneven heating of various parts of the workpiece, resulting in the deformation of the workpiece.

3. Clamping of workpiece

Some metal materials have poor rigidity, such as aluminum alloy. The elastic deformation caused by clamping and pressing will affect the accuracy and shape of workpiece surface size.

4. Influence of workpiece materials

Aluminum alloy has always been an important metal in aerospace industry. Compared with other metals, aluminum alloy is lighter and easier to be cut. However, aluminum alloy and other metals are prone to produce chemical reactions, and aluminum alloy has relatively low hardness and large plasticity. These three properties lead to aluminum alloy deformation in the cutting process.Due to the low hardness and high plasticity of aluminum alloy, chip accretion is easy to occur in the cutting process, which seriously affects the machining accuracy and the surface quality of workpiece.

5. Influence of cutting tool lowering mode

The influence of vertical feed mode on Web machining accuracy and the influence of horizontal feed mode on sidewall machining accuracy are objective.Three ways of vertical feed are designed for CNC machine tools: one is direct vertical feed; the other is oblique path feed; the third is spiral path feed.It is significant to choose the proper cutting way to reduce the machining deformation.

Xiangbo has different solutions for the elimination of residual stress of various workpieces.

1. The solution of stress relief for large and medium-sized structural parts

For the elimination of residual stress in large and medium-sized structures, Xiang Bo adopts the self-developed spectrum harmonic aging technology, uses the Fourier analysis method to analyze the frequency spectrum of the workpiece, finds out dozens of harmonic frequencies of the workpiece, and then selects five frequencies to deal with the workpiece, so as to reduce and homogenize the residual stress in the process of casting, forging, welding and processing, and improve the workpiece scaleInch accuracy stability, prevent deformation and cracking.

2007In, a large-scale aerospace equipment manufacturer used spectrum harmonic aging. For its ring forgings, aging treatment was carried out after roughing, roughing and finishing. Finally, the dimensional accuracy of the forgings completely met the design requirements, and helped the enterprise greatly save time. Finally, it was included in the manufacturing process specification of launch vehicle.

2. Solution of stress relief for light thin wall parts

Mode wide-band aging technology is a new generation of aging technology independently developed by Xiangbo technology aiming at the residual stress problems concerned by high-end manufacturing industries such as aviation and aerospace. The frequency range is 0-1000hz, which can better meet the stress relief needs of small and medium-sized plates, plates, rings, frames and other parts.

Due to the advantages of on-line dynamic adjustable exciting force and high accuracy, modal broadband aging is widely used in the fields of aviation, aerospace, weapons, transportation, ship, energy, electronics, communication industry, etc., especially for the turbine disk, blade, gearbox of aeroengine; light thin-walled parts such as cylinder block, cylinder head, crankshaft, connecting rod of automobile.

Case presentation:

A nickel base superalloy aeronautical part

Workpiece material: GH4169

Blank structure: 860mm diameter ring

Forming method: Ring Rolling

Machining mode: Turning

Finished structure: Ring thin-walled parts

Processing technology: blank → roughing → heat treatment → semi finishing → finishing → finished product

Problems occurred: after heat treatment, the workpiece was deformed and cracked, unable to meet the acceptance standard.

terms of settlement:X-ray residual stress detection equipment is used to detect the residual stress of the workpiece before aging, and the distribution of the residual stress of the workpiece before aging is obtained.

The finite element analysis software is used to calculate all the modal frequencies and modes of the workpiece in the range of 0-1000hz under different clamping conditions, so as to optimize the optimal excitation frequency, mode and the corresponding clamping mode, and the workpiece is aged by the mode wide frequency aging center.

Effect:After aging, the tangential stress, the axial stress and the equivalent stress of the end face measuring point decreased obviously, which met the standard requirements.

3. Multi process continuous simulation

Products in the field of aviation manufacturing must go through the process of single piece or small batch trial production, process shaping and batch production before they are put into production. The materials and processing costs of the trial parts are expensive, not to mention that traditional process shaping often needs to go through a certain exploration cycle. If there are problems, it is difficult to locate the causes of the deformation of the parts and solve them, then digital process simulation is needed.

3D printing simulation of complex structure

The multi process continuous simulation software developed by Xiangbo technology based on ABAQUS is a process analysis software that can realize multi process and multi-step process continuous analysis, and can simulate the multi-field coupling large deformation and highly nonlinear process of the process.The purpose of multi process continuous simulation software is to realize the simulation of the whole process physical process of the manufacturing process of mechanical products or parts, and to assist the design, verification and optimization of the manufacturing process of products or parts.Multi simulation software is oriented to technologists, providing friendly interface, simple operation, shielding complex numerical calculation features, so that users only pay attention to process simulation itself.

Different scenes, Xiangbo has different unique skills to solve.Since its establishment, Xiangbo has been committed to solving the problems of residual stress and machining deformation in the machinery manufacturing industry, with the ability of residual stress detection, residual stress elimination and digital process simulation, and has persisted in independent research and development, developed independently innovative products, technologies and advanced solutions, especially in the stress and deformation control of light thin-walled metal partsThe world's leading position, has obtained dozens of software copyright and patents.In the future, Xiangbo will firmly follow the path of combining production, learning, research and use, and make more contributions to China's aerospace industry.