Semboo Navigator Expert System for VSR

发布时间:2019/12/12

1、VSR Definition

It refers to a physical process of dealing with the metal work piece through vibration power strictly controlled, with a view to solving the problem of instability of dimension and anti-overloading capacity caused by the internal residual stress both during and after processing the work piece. VSR is especially effective to relieve, reduce or homogenize the residual stress within the metal work piece, to improve dynamic and static anti-overloading and distortion-proof capacity of the work piece, and to make sure the dimension and scale accurate.

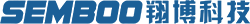

Figure 1 Semboo Navigator VSR diagram

Figure 1 Semboo Navigator VSR diagram

2、Principle of VSR

The micro-analysis shows that VSR can be taken as an additional stress imposed on the work piece in the form of recycling loading. The alternating stresses imposed on the work piece and the residual stress within the work piece overlap when the work piece is vibrating. When the overlapping of the stresses reach a specific limit, the part where the stress most concentrates will exceeds the yielding limit of the material and distorts , which will reduce the peak value of the residual stress and harden the metal itself. Afterwards, the vibration will work similarly on other parts where the stress concentrates, to the effect that the total value of the overlapping additional vibration stress and the residual stress will not cause any plastic deformation of the work piece, which marks the end of the process to relieve and homogenize the residual stress and harden the metal through vibration.

3、Semboo Navigator VSR Advantages

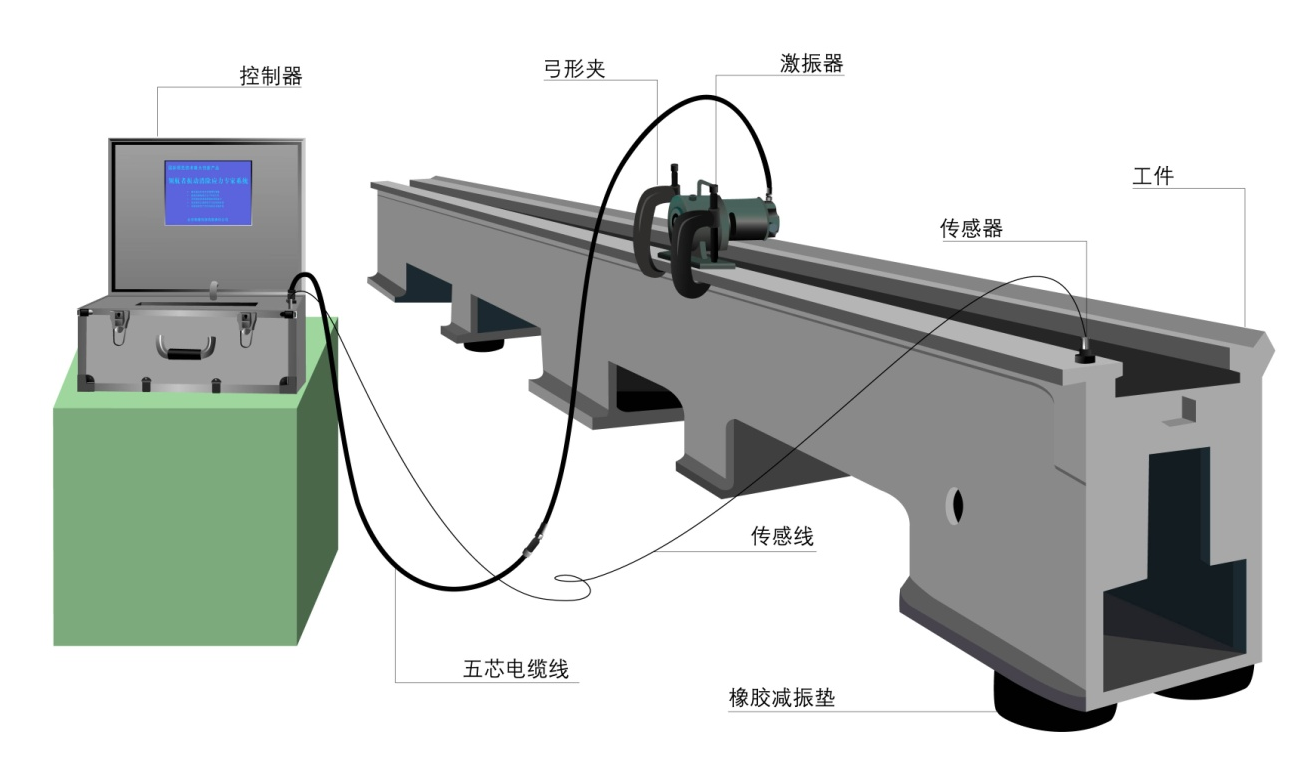

A、Patented harmonic frequency spectrum VSR

(The world's only patented technology for spectrum harmonic aging,patent number:ZL2005100929856)

B、Handle over 90% of metal workpieces

C、No special requirement for positioning of sensor and vibrator

D、Widely applied, especially for workpieces with high rigidity, high tonnage, and high natural frequency

E、Harmonic Frequency spectrum analysis,No need to scan

F、Vibration frequencies selected are all below 6000rpm, low frequency, low vibration noise, and environmental friendly.

G、Without relying on the skills and experience of the operator, different operators can achieve a constant processing effect by using this equipment