Residual stress testing service

发布时间:2020/03/27

Purpose of detection

Residual stress is the key evaluation index of the surface integrity quality of parts, which directly affects the crack failure, machining deformation and dimensional stability of parts. Through the detection and quantitative analysis of residual stress, it can provide quantitative basis for the evaluation of processing technology and process optimization, realize the analysis and targeted solution of parts deformation and failure, realize the health monitoring and quality acceptance in the development and production process, and improve and ensure the quality of product delivery.

Testing Center

Beijing Semboo Science&Technology CO.Ltd. and Beijing University of Aeronautics and Astronautics, the first university of Aeronautics and Astronautics in New China, established a joint laboratory for residual stress and deformation processing control, and a testing center of Beijing Semboo Science&Technology CO.Ltd.,which is based on the research strength of the laboratory.

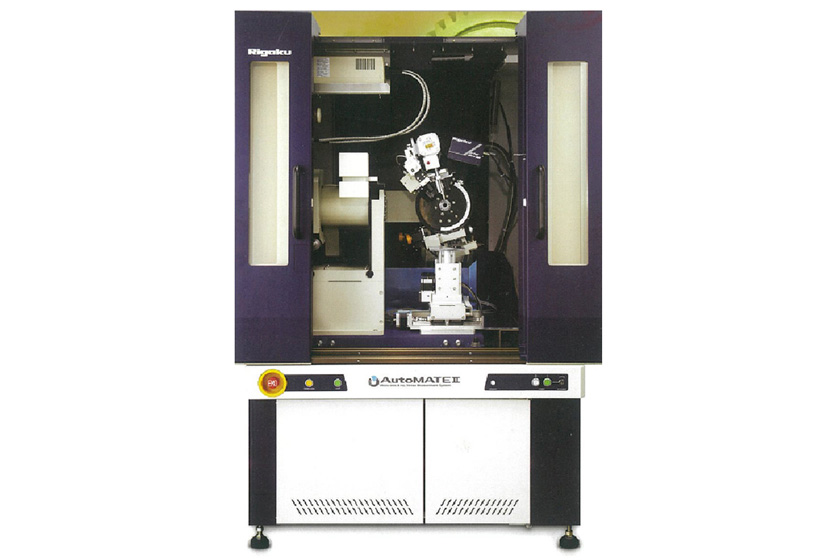

The center has a number of international most advanced X-ray line shooting residual stress analyzers and high-end electropolishing equipment, mainly for metal workpiece deformation, cracking, dimensional accuracy instability, fatigue life, static strength, stress corrosion, etc., to carry out residual stress detection, evaluation and application research in related technical fields.

The center has more than ten postdoctoral, doctoral and master's researchers in solid mechanics, material mechanics, nondestructive testing, mechanical manufacturing, control engineering and other disciplines, many of whom have participated in or are participating in national 973 and 863 projects. With professional technical team and advanced equipment, the testing center can ensure the rapid and accurate detection and analysis of residual stress, and ensure the professionalism and authority of the evaluation results.

Our center has been engaged in testing business more than 15 years, and has tested more than 100000 pieces of stress information so far, serving customers in various fields such as aviation, aerospace, weapons, ships, nuclear industry, rail transit, automobile, etc.

Inspection Service Introduction

The testing center has a professional testing team. The testing methods include X-ray diffraction method and blind hole method. There are many types of equipment and many advanced equipment imported from abroad. We can choose the appropriate methods and equipment according to the needs of customers, which can accept the incoming part testing and provide on-site testing services. Relying on our company's professional technical team of residual stress and deformation control research, we can carry out residual stress detection, evaluation and application research services in related technical fields for metal workpiece deformation, cracking, dimensional accuracy instability, fatigue life, static strength, stress corrosion, etc.

Applicable materials

Aluminum alloy, titanium alloy, carbon steel, stainless steel, copper alloy, nickel base alloy, ceramics, etc.

Service advantages

1. Qualification guarantee:

The testing center of our company has obtained the laboratory accreditation certificate (CNAs) of China conformity assessment and Accreditation Commission since November 2014. The CNAs quality system has maintained operation and passed the previous review and version change review, and completed the version change and expansion review by November 2019. So far, the testing methods certified by our testing center include GB / T 7704-2017 nondestructive testing X-ray stress measurement method, nondestructive testing X-ray stress measurement method DRS method, and GB / T 3395-2013 residual stress detection method borehole strain release method. The center will, as always, provide customers with professional and comprehensive residual stress detection services with credibility.

Beijing Semboo Science&Technology CO.Ltd. has obtained the laboratory accreditation certificate (Registration No.: CNAs l7277) issued by China National Accreditation Committee for conformity assessment, and the national high-tech enterprise and national intellectual property management system certification. Its customers cover the mechanical manufacturing fields of aviation, aerospace, weapons, ships, engineering machinery, printing and brushing machinery, mining machinery, automobiles, molds, machine tools, wind power, etc.

2. Talent assurance:

The testing center has more than ten professional researchers who master nondestructive testing technology, and an expert team of overall solutions for residual stress and deformation control;

3. Service guarantee:

The center has a number of internationally advanced X-ray diffraction residual stress analyzers, with various options, which can provide not only incoming inspection services for small parts, but also door-to-door services for large workpieces;

4. Equipment support:

The stress instrument introduced by the center can measure the residual stress of the same point in all directions flexibly and accurately, and realize the digital detection; through the multi-point and multi-directional measurement, the complete cloud chart of the stress distribution of the workpiece can be drawn.